I have owned my TVR Griffith 500 for 5 years now, originally purchased from James Birkby at TVR MADS in 2009. The Griff was low mileage completely standard example of the marque which had been meticulously cared for by its previous owners.

During my ownership in addition to the usual servicing requirements the car has undergone a number of subtle enhancements to improve driveability, performance and reliability. Importantly for me the look of the car remains completely original. I would like to think that the modifications I have completed have not devalued the car as they are all generally viewed as excepted and well-known enhancements in the TVR community. All modifications I have completed on the car are 100% reversible and I have always kept the original parts so if I ever do need to return the car to a factory standard state I am able to do so.

The engine is still largely standard but I have added a number of breathing and fueling modifications to help the engine work more efficiently. Breathing modifications include a full ACT replica stainless steel exhaust manifolds, Clive Ford Y piece, ACT smooth bore induction hoses, carbon fibre superflare trumpets, K&N panel filter element and an inlet thermal gasket. On the fueling side I have modern Bosch spray pattern fuel injectors, larger Bosch Air flow Meter and an uprated Bosch 3 bar fuel regulator. The ECU is original Lucas 14CUX which has been remapped by Rover V8 mapping guru Mark Adams. The result is a very smooth power delivery, more torque and BHP throughout the rev range and better fuel economy. Bad habits such as cold start issues, lumpy idle, low speed shunting and cold start issues have all been removed. Those who have 5.0 Rover V8 TVRs will know all about shunting, especially on a hot day!

The car is pretty much where I want it to be now and I am very pleased with it. However there is one product that I have always lusted after, the ACT twin throttle carbon fibre plenum. After being drawn in by the aesthetics of the product, whenever I have spoken with an owner who has one fitted to their car they have always expressed how impressed they are with it.

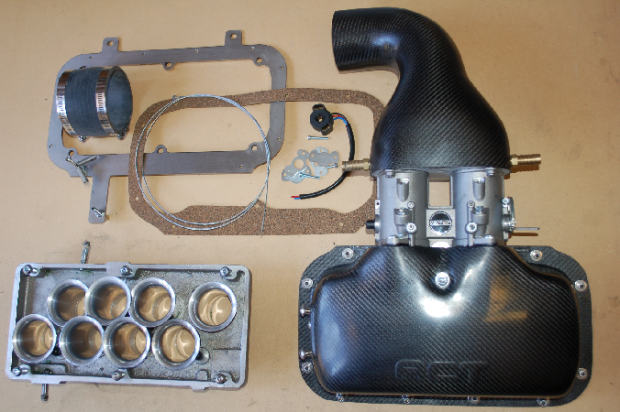

I have got to know Tim Lamont who runs ACT products well having purchased a number of parts from him over the years. Tim is always very honest about the products he sells and there is never any element of hard sell. All the ACT products I have purchased have always been very good quality. I have been speaking to Tim on and off for a couple of years regarding the plenum. My Griff has the standard Land Rover plenum chamber fitted which, when originally designed was optimised for low speed torque. Great for heavy 4x4s but perhaps not ideal for a sports car. The ACT plenum kit has been designed to feed in air more effectively across the trumpets. Instead of a single throttle the ACT plenum has two Jenvey throttle bodies which are positioned to further optimise the airflow over the trumpets. With better air distribution comes additional torque and power and a much improved throttle response.

ACT also offer a triple throttle variant of the carbon fibre plenum. I have always preferred fit of twin throttle plenum on the Griff. The pipework on the twin plenum follows the exact same route as the original plenum whereas the triple comes across the rockers exposing some of the ducting. I spoke with Tim regarding the differences between the two in terms of performance and he recommended the twin throttle over the triple in my case as it would be more than sufficient fitted to a TVR 5.0 Rover V8. The benefits of the triple throttle version would only really be noticeable over the twin on high output custom-built engines, for example the V8 Developments 5.5 and some of the higher capacity John Eales racing engines.

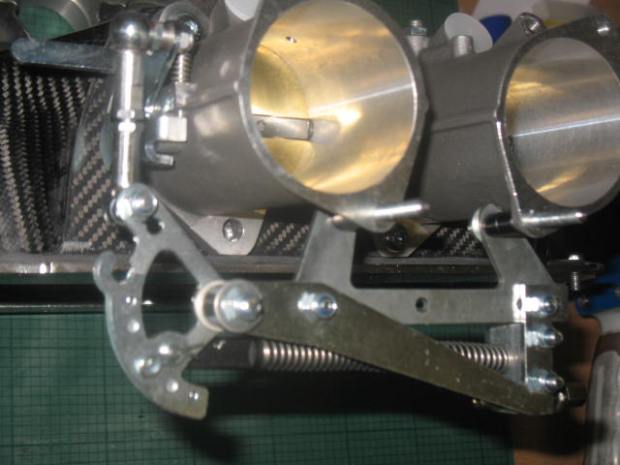

After speaking with a fellow Griff owner in Holland he advised me to also fit an upgraded throttle linkage to the plenum kit which bolts directly to the throttle bodies. The linkage he had fitted to his ACT plenum looked improved over the original design. I spoke with Tim at ACT about the upgraded linkage and the possibility of him supplying a plenum kit with this included as part of the build. Tim had previously been working with Jenvey on an upgraded linkage option for the plenum kits and already had some test units in the workshop. In addition to the upgraded linkage mechanism looking better engineered it also features an improved return spring that compresses as the throttle opens as opposed to stretching the spring. There are no performance benefits but input to the throttle pedal will be more precise and it should have a better feel. You can see the difference between the existing linkage design and the new upgraded version in the images below:

I found myself in a position this year to place an order for the plenum kit with the upgraded linkage. Once the plenum had been built Tim needed to test the final fit and clearance of the new linkage being the first production item to feature the upgrade. The plenum was test fitted to a car at Austec and everything checked out fine.

I had the plenum fitted to the car while it was in for it’s 12k service. I entrust my Griff to David Batty and his team at ‘The Garage’ in Godalming. David is someone I have a lot of respect for as he has been in the game a long time and is a very experienced and talented mechanic. Unlike many other mechanics I have dealt with he listens carefully to what the customer wants before offering a solution and always takes the time to explain things in mild mannered way. The business is family run and very friendly. I am certainly not the easiest customer deal with as I do have OCD tendencies when it comes to my Griff and I expect work that is carried out by a TVR specialist to be of the highest standard. I have always been extremely happy with the work that David and his team have completed on my car and have always found him a pleasure to do business with.

As expected David did fantastic job of fitting the plenum kit. It took a little bit longer than expected to fit as my car has power steering and is running the original coil both of which are bolted to the old plenum. A number of other cars I’d seen with these plenums didn’t appear to have power steering and most had aftermarket ECUs which utilise coil packs mounted elsewhere in the engine bay. I was keen to keep the power steering reservoir and coil in the original location so Tim and David came up with a neat solution to modify the existing brackets and retain these items.

I bought an old pair of Rover SD1 rockers from eBay and had them powder coated in a black crinkle finish which David also fitted. The flame trap is one of Clive Letherby’s CNC masterpieces (Point CNC).

Once the plenum was fitted and the car services I asked David to use the car for a couple of days to give it a shakedown before I picked it up and to let me know his thoughts. When I spoke to David on the phone to ask his opinion he said to me “Matthew, I think you are going to be very pleased with the result”.

I have only had the plenum fitted for a couple of weeks but I must say I pleased would be an understatement. I have always found the throttle response on the Griff to be a bit lethargic, great for bumbling around riding the torque band but never really that impressive when pressing on. The plenum has changed the character of the car completely; it feels much more free-revving and eager to go just like a modern sports car but with the TVR grunt that we all know and love. This is so far the most noticeable modification I have completed performance wise. The car has always pulled like a train but now it goes like a rocket. The car feels like it has noticeably gained top end power, I used to change up around 5k revs before but now it pulls strong all the way up to 6k. The main difference however is the throttle response which is now unbelievable; any input on the throttle pedal is now instant. I am also very pleased with the throttle pedal weight which is much lighter than the old setup but not so light that it lacks feel. The old setup was fine most of the time became tiresome in traffic and on long motorway journeys. I do not have any definitive figures from the dyno yet but I normally dyno the car once a year so it will be interesting to see how the graph has changed compared to last year.

The only minor downside with the plenum is the chatter from the valve train is noticeably louder, I assume the original plenum being thicker deadened the sound. That said this isn’t really an issue as I have only noticed the difference when on idle and with the roof off.

I spoke to Tim to feedback my thoughts on the plenum and the new linkage. I said that I thought the car had gained a lot of power and he explained that he tested the product on a dyno with a new John Eales 4.3 engine and ACT plenum made an extra 10BHP when tested back to back against the standard rover item. Tim went on to explain that it is not just down to the increase in peak torque and power that makes the car feel quicker in the case of this product, it is the delivery of power throughout the rev range and the throttle response. Tim said when he was originally developing the plenum he fitted the product to an RV8 race car and the car lapped significantly quicker with the new plenum. Although the plenum would have only added around 10BHP peak power the lap times reflected increase in equivalent of around 50BHP peak power. The reason the lap times had fallen where largely down to not the peak power but the delivery of the power. The improved throttle response meant the driver was able to get back on the power quicker out of the corners and benefitted from an increase in mid range torque and power. An interesting story and now having done a track day with the plenum I can certainly believe that claim.

In summary I am very impressed with this product and would thoroughly recommend it. I am particularly pleased with the new linkage as for me I have always seen the original linkage as a weak point of what is otherwise a beautifully crafted and cleverly engineered product. I understand from Tim that the new linkage is now available as a retrofit option for existing customers with the old linkage.

2016 Rolling Road Update

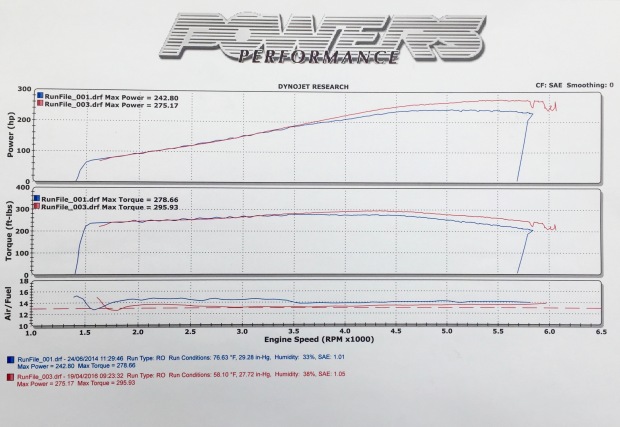

I have had the camshaft replaced as the standard TVR435 item was badly worn. I opted for the TVR Power 885 cam fitted by David Batty. I took the car up to TVR Power in Coventry to be run on the rolling road. The last time I had the car run was in 2014. The result with the combination of the cam and the plenum was very impressive. Power up from 242.8BHP to 275.2BHP measured at the wheels, approx 286BHP to 324BHP at the flywheel. The rolling road result showed the extra breathing provided by the plenum at the top end.

This modification was featured in Sprint Magazine June 2014

Link to article